Precision Engineering: Explore the Unmatched Quality of China's Best E-Motorcycle Connectors for Global Markets

In the rapidly evolving landscape of electric mobility, the demand for high-quality E-Motorcycle Connectors has surged, driven by the global push towards sustainable transport solutions. According to a report by MarketsandMarkets, the electric motorcycle market is projected to grow at a CAGR of 7.6%, reaching $23.8 billion by 2027, highlighting the increasing importance of reliable components. China, recognized as a manufacturing powerhouse, is leading this charge by producing top-tier E-Motorcycle Connectors that meet international standards of quality and performance. These connectors play a critical role in ensuring the reliability and efficiency of electric motorcycles, directly impacting their performance and safety. As global markets seek innovative and dependable solutions, the unmatched quality of China's best E-Motorcycle Connectors positions them at the forefront of this transformative industry.

The Rising Demand for E-Motorcycle Connectors in the Global Market

The global market for e-motorcycle connectors is witnessing a significant surge in demand, driven by the increasing popularity of electric vehicles and the growing need for efficient connectivity solutions. As more consumers embrace eco-friendly transport options, manufacturers are in turn prioritizing high-quality connectors that enhance performance and reliability. China's prowess in precision engineering has positioned it as a leading supplier of connectors that meet international standards and cater to diverse market needs.

When choosing e-motorcycle connectors, it's crucial to consider factors such as durability and compatibility with various electrical systems. Look for connectors that offer weather-resistant features to ensure optimal function in diverse environmental conditions. Another important tip is to ensure that the connectors are designed for easy installation and maintenance, which can save time and reduce costs in the long run.

Moreover, understanding the specific technical requirements of your e-motorcycle can greatly influence the selection process. Always keep an eye on the latest technological advancements to ensure that you are equipped with the most innovative solutions in the market. By making informed decisions, manufacturers can enhance the overall performance of their e-motorcycles, ultimately leading to greater consumer satisfaction.

Precision Engineering: Explore the Unmatched Quality of China's Best E-Motorcycle Connectors for Global Markets - The Rising Demand for E-Motorcycle Connectors in the Global Market

| Connector Type | Application | Market Demand (Units) | Growth Rate (%) | Key Features |

|---|---|---|---|---|

| High Voltage Connectors | E-Motorcycle Power Systems | 250,000 | 15% | Durability, Waterproof, High Conductivity |

| Battery Connectors | Electric Drive Units | 300,000 | 20% | Lightweight, Low Resistance, Energy Efficient |

| Charging Connectors | Rechargeable Battery Systems | 350,000 | 25% | Fast Charging, High Compatibility, Safety |

| Signal Connectors | Control Systems | 200,000 | 10% | Compact Design, Reliable Transmission |

| Temperature Sensors Connectors | Motor Temperature Monitoring | 150,000 | 5% | High Sensitivity, Tolerance to Harsh Environments |

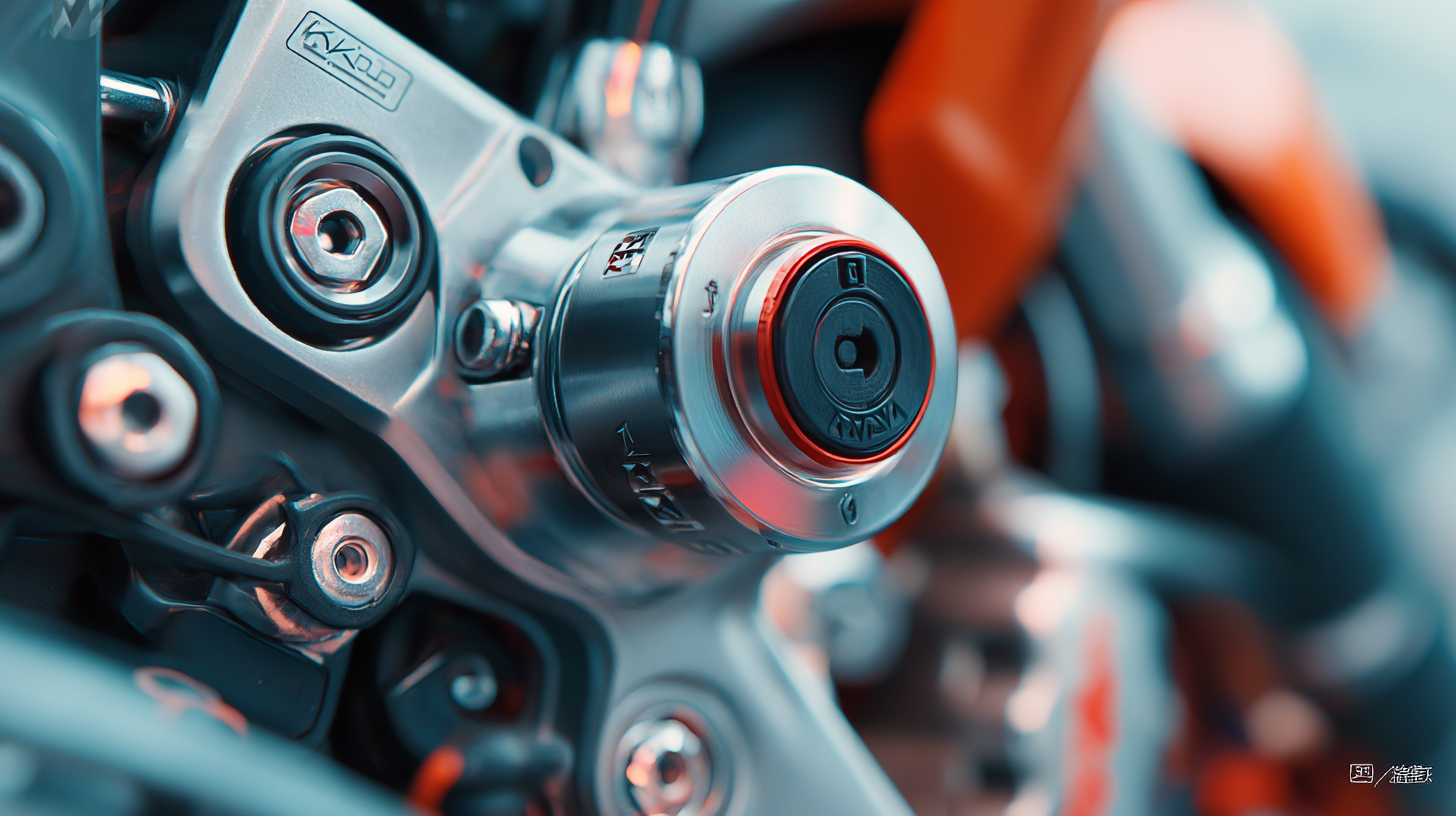

Technological Advancements Driving Precision Engineering in E-Motorcycle Components

Technological advancements are undeniably reshaping the landscape of precision engineering, particularly within the electric motorcycle industry. As electrification progresses, it has led to significant innovations in e-motorcycle components, including connectors that ensure seamless integration, safety, and performance. The global electric vehicle (EV) battery-manufacturing sector is poised to witness an output of over 1,037 GWh by 2028, underscoring the demand for high-quality components in the automotive market.

China stands at the forefront of this revolution, driving substantial growth in its auto parts market, which is projected to reach USD 212.4 billion by 2035 at a CAGR of 6.02%. This growth is propelled by the need for precision-engineered connectors that can withstand the rigors of modern e-mobility. With a growing inclination toward sustainable solutions, manufacturers are increasingly focusing on integrating advanced technologies such as IoT and advanced sensors to enhance the performance and functionality of e-motorcycles.

The transformative phase of the motorcycle parts market is further highlighted through the key trends of increased connectivity and improved safety features. As industries globally adapt to shifting consumer preferences and environmental imperatives, precision engineering stands as a cornerstone for delivering unmatched quality and reliability in e-motorcycle components, ensuring they meet the demands of both local and international markets.

Key Manufacturing Processes for High-Quality E-Motorcycle Connectors

In the realm of e-motorcycles, the quality of connectors plays a pivotal role in ensuring optimal performance and durability. China has emerged as a leader in producing high-quality e-motorcycle connectors, thanks to its advanced manufacturing processes. Key to this success is the emphasis on precision engineering, which minimizes defects and maximizes reliability. The use of cutting-edge technologies, such as automated assembly lines and advanced testing equipment, guarantees that each connector meets stringent international standards.

Furthermore, the manufacturing processes involved in creating these connectors include meticulous design optimization and material selection. Manufacturers often utilize high-conductivity materials that are resistant to corrosion and wear, enhancing the longevity of the connectors. Techniques such as injection molding and surface treatment are also critical, as they improve not only the physical properties of the connectors but also their performance under varying environmental conditions. By focusing on these key processes, Chinese manufacturers are setting a new benchmark for quality in the global e-motorcycle market, catering to the growing demands for reliable and efficient electric vehicles.

Market Trends and Projections for E-Motorcycle Connector Growth by 2025

The global e-motorcycle connector market is poised for significant growth, with projections indicating an increase from $2.5 billion in 2023 to $4.5 billion by 2025. This surge can be attributed to rising demand for electric vehicles (EVs) and advancements in precision engineering technologies. According to a recent market research report by Industry Insights, the e-motorcycle segment is expected to experience a compound annual growth rate (CAGR) of over 25% during this period, reflecting a shift in consumer preferences towards environmentally friendly transportation solutions.

Moreover, innovations in connector design are making e-motorcycle connectivity more efficient and reliable. High-performance connectors are essential for ensuring seamless communication between electric motors, batteries, and control units. As highlighted in the DataBridge Market Research report, with the growing emphasis on lightweight materials and durability, manufacturers are increasingly focusing on developing connectors that can withstand harsh environmental conditions while maintaining performance—setting a new standard for quality in the e-motorcycle market.

Top Chinese Manufacturers Leading the Charge in the E-Motorcycle Connector Industry

China is rapidly becoming a global leader in the e-motorcycle connector industry, with top manufacturers pushing the boundaries of precision engineering. These companies are not only focusing on high-quality materials and innovative designs but are also committed to meeting international standards. This commitment ensures that their products are not just suitable for local markets, but also competitive on a global scale. By combining advanced technology with rigorous quality control, these manufacturers stand out as key players in the fast-growing e-motorcycle sector.

**Tip:** When selecting e-motorcycle connectors, it's crucial to consider the environmental factors they will be exposed to. Opt for connectors that offer robust weather resistance and are made from durable materials to ensure longevity and performance.

As the demand for electric motorcycles increases, collaboration among the leading Chinese manufacturers is fostering innovation and technology transfer across the industry. This harmonious development enhances not only the product offerings but also elevates customer satisfaction. Manufacturers who focus on research and development are setting new standards for efficiency and reliability in connector systems.

**Tip:** Always check for product certifications and user reviews before making a purchase. This will help in ensuring that you choose a connector that is both reliable and well-suited for your specific e-motorcycle needs.